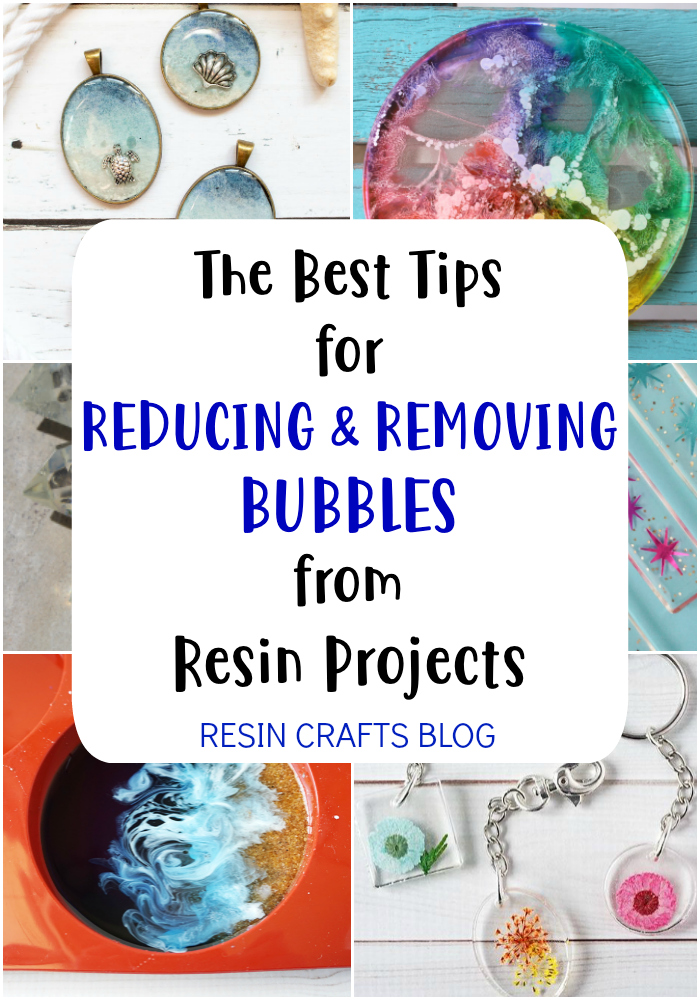

Bubbles in an epoxy pour can be one of the most frustrating parts of resin crafting. Follow these 6 best tips to reduce and eliminate bubbles from your resin projects!

Hello, friends! We have loved getting to know some of you better over in our Facebook VIP group. We take notes on your feedback and questions to help us come up with the content that we share with you.

One of the most common questions/concerns we hear about is bubbles in resin pours. We agree… it’s a major bummer!

Jane from Sustain My Craft Habit did a Facebook Live in our Resin Crafting Facebook group a couple of months ago to review the top 6 tips to reduce bubbles when working with resin. Check out her video at the bottom of this post for helpful details on each step!

Top 6 Tips for Reducing Bubbles in Your Resin Projects

- Warm bottles of epoxy prior using. Cold resin (or even room temperature sometimes) is almost certain to form many micro bubbles throughout the entire resin pour that will form throughout the curing process which will be impossible to remove. Place the closed containers into a warm bucket of tap water for 20 minutes. The bottles should be warm to the touch before mixing.

- Seal surfaces of any objects prior to coating with epoxy with Ultra-Seal or any clear-drying water based glue.

- When mixing the resin and hardener, mix slowly making sure to scrape the sides and bottoms of the mixing container. If epoxy is stirred fast it creates more bubbles. If bubbles are visible during the mixing process use your stir stick and push the bubbles up against the side of your mixing container to pop them.

- When pouring your epoxy into a mold, pour very slowly and from one side of the mixing cup into one side of the mold.

- After resin has been poured, wait about 10 – 15 minutes and use a propane or butane torch, making sure to keep 6 to 8 inches above the surface. This helps bring the bubbles to the surface. A long arm butane lighter can also be used. Depending on the depth of the resin pour, you can repeat this a couple of times throughout the curing process.

- If bubbles are present in cured piece, use a razor blade to pop the bubbles and create an open cavity. Mix a small amount of epoxy to fill in those holes; let cure for 5 hours then re-flood surface.

Lydia Nordhoff is the creator of Lydi Out Loud, a blog where she shares her adventures in crafting and DIY. Lydi Out Loud has been featured on the Home Depot Blog, House Beautiful, Good Housekeeping, Southern Living, Elle Decor, Brit + Co., Buzz Feed, Cricut and Somerset Home Magazine.

Thank you very much for giving us these really great tips. Bubble are always a pain and I’m liking your tips. Some of these I never heard. Thanks again and keep on crafting!

Thank you so much for these tips. This is one of my biggest problems that I continue to have. I have started putting my stirred resin in hot water to heat it up and that seems to help. One of my other issues is that I get cracks or voids in my piece when I pour in layers. Any ideas on why?

Hi Becky, how long are you curing between layers?

Thank you soooo much for your tips!! What about using alcohol to get rid of the bubbles once they are in the mold and waiting to cure?

Hi Jodie! You can do that as well, it will disapate small surface bubbles a little bit. You wouldn’t want to use too much as it could disturb the cure. These other tips are our favorites.

Hi Lydi,

I’ve never used Envirotex before and just poured it on two coasters. I got all of the bubbles out with carbon dioxide but, how long before it’s safe to cover the project to cure (I’m using a big box). They look great now (1 hour after pour) but I’m so nervous about ruining it. Thanks so much!

Hi Mary, you’re good to go ahead and cover after an hour for sure!