Let’s pretend that Mondays mold making disaster was a dream.

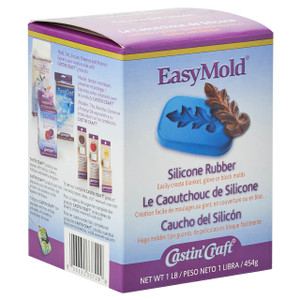

If you have a large object, like this wood bangle, the easiest way to make a mold is with EasyMold Silicone Rubber.

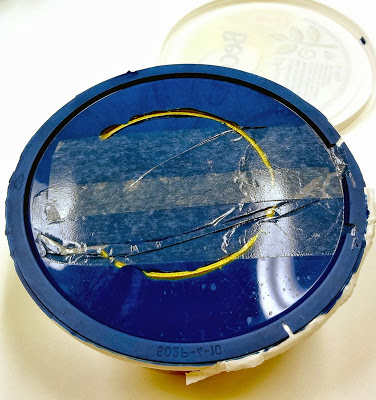

Your object can be placed in an open container like this one.

I use margarine tubs. The margarine lid is on….ultimately the lid is the bottom during the mold making stage. (I cut away the real bottom as you can see in the picture.)

I HOT GLUE MY OBJECT to the bottom of my container so it DOES NOT MOVE after I pour in my Mold Builder Liquid Latex Rubber.

This is EasyMold Silicone rubber.

- Brushable/Pourable

- 45 Minute to 1 hour working time, 24 hour cure. Cure rate can be adjusted by applying heat.

- Produces extremely fine detail from original, no shrinkage.

- Self releasing, no mold release agent required for most applications.

- High heat range, up to 400º F.

- Strong flexible re-useable molds.

- No vacuum equipment required.

Here is my rubber curing after I poured it into my container.

24 hours later I take the lid off. This gives me a chance to now slide out my mold.

Ta Da! Mold is perfect. I will now remove the original wood bangle and start pouring resin into this new mold.

This is really cool – and can be done with so many different items!

Looks great! I was wondering, have you ever tried to anchor your cast piece with clay instead of hot glue? I've done it with some success. Also, is the EasyMold Silicone self-degassing? I see it needs no vacuum equipment.

Clay does indeed work…I just don't have any in my studio.

The silicone rubber does indeed self de-gass. I have one more how-to showing you some tips on that too! (if you can't wait they are included in the instructions.)

Have you ever heard of using one of these molds for ceramic.slip?

That’s an interesting idea. For something like the bracelet, it seems like it would break before you could get it out of this mold as-is. Hm… I suppose the mold could be cut apart before casting and shims made of lightweight sheet metal (brass, copper or aluminum roof flashing) could be placed in a few (two?) strategic places. That could allow the mold to further separate to remove the brittle clay once dried to leather stage. Your question got me thinking!

I have not tried that so I would recommend you ask customer service for ETI.http://eti-usa.com/contact/

Curious how you got bracelet out and what it looked like afterward.

Hi Tammi! Since the mold is silicone rubber it literally just peels right off with no effect on the product that the mold was made from.

How would you create a new cellphone cover with it? Bought a new brand of phone and can’t find a cover to match.

Hi Sandy, you would need to have a cover to make the mold from because you wouldn’t want to use your phone to create a mold.

I’ve seem folks use parchment paper to wrap their phone in (the paper glued just enough to hold closed) to make hot glue cases over the top of the parchment. I’ve not used the rubber mold stuff here, but if it was very thin and viscous, it may penetrate the folds of the paper. I wonder – does this casting compound give off any significant heat? Using an existing cover though does seem to be the safest route.

I may be asking questions and making comments here way too far after the original questions, but I do very much appreciate the fact that it is still here for noobs to resin casting/molds like me.

HI there Patty! It is not thin it’s quite thick so it shouldn’t penetrate. No it doesn’t give off any heat.

Silicone Rubber is certainly a superior material to mold into the different shape, size or products, but the way you have explained the complete procedure is amazing.

Anyone can try it at their own convenience. Thanks

Did this make a SHINY surface mold for resin bangles? I had wondered if coating object with shiny gloss nail polish would give a mold that is shiny?

Hi Lisa! We don’t want to coat the mold with anything as it could interfere with whatever object you are making with the mold releasing from the mold.

I am trying to make molds of my dolls head not to big can you please

Help with what of material I can use thank you I’m trading to make molds for pods

Hi Luz! The silicone rubber material is a great choice.

Can this be used to make a mold of styrofoam objects? Or would it eat the styrofoam.

Hi Tammy, styrofoam wouldn’t have enough strong body to pull away the mold and release fully.

Would this silicone rubber work for making a mold of a larger object? I need to cast a 2″ thick piece of treated wood measuring 10×12. I plan to set it in a large aluminum pan. Can I combine multiple containers of product to get enough to make the mold?

Hi Rebekah!

Silicone Rubber is recommended for large molds.

My only concern would be making sure the rubber is mixed thoroughly, which can be difficult in large volumes.

Wood must be sealed to prevent the rubber from soaking into pores/holes.

Seal with a few layers of fast drying acrylic clear coat.

I hope that helps and please let us know if you have any other questions!

Have you used this to make a cast from bone? I have a found animal skull that I would like to make a mold from, but I worry about how well the rubber will release from the bone surface.

I haven’t but I’ve seen it used on very porous surfaces and it releases. You could also spray some mold release for extra assurance. 🙂

Hi! Do you know if you can use this mold for cement instead of resin?

Thanks!

You sure can!

How do you determine the amount required please ????

Hi Samantha! This a great video that demonstrates how to get the amount you need! https://eti-usa.com/easymold-silicone-rubber-liquid/

Hello I have five cricketers all 2 foot tall solid concrete I would like to make a mold how do I start please advise I will buy whatever material I have to have

Hi Len! Alumilite has the best mold-making materials for this type of application. It will take a lot but sounds very cool!https://www.alumilite.com/products/silicones/